A line of excellence that encompasses the selection of the best parts of the tuna and the fillets with the best state of preservation and firmness of the meat.

Senaka differs from the other products in the group because it is packaged in ATM (Modified Atmosphere) using gas. Its maturation also takes place in ATM, which is observed to ensure the highest levels of quality.

Senaka is designed to conquer the best tuna markets around the world.

Safety Procedures

Our

Laboratory

At our laboratory, Mar Grande, we combine the tradition of fish processing with modern technology.

We focus on quality at all stages, from the preservation of the cold chain to the constant meticulousness in handling the raw material.

Therefore, we enhance the organoleptic properties and avoid wasting the priceless good that nature gives us.

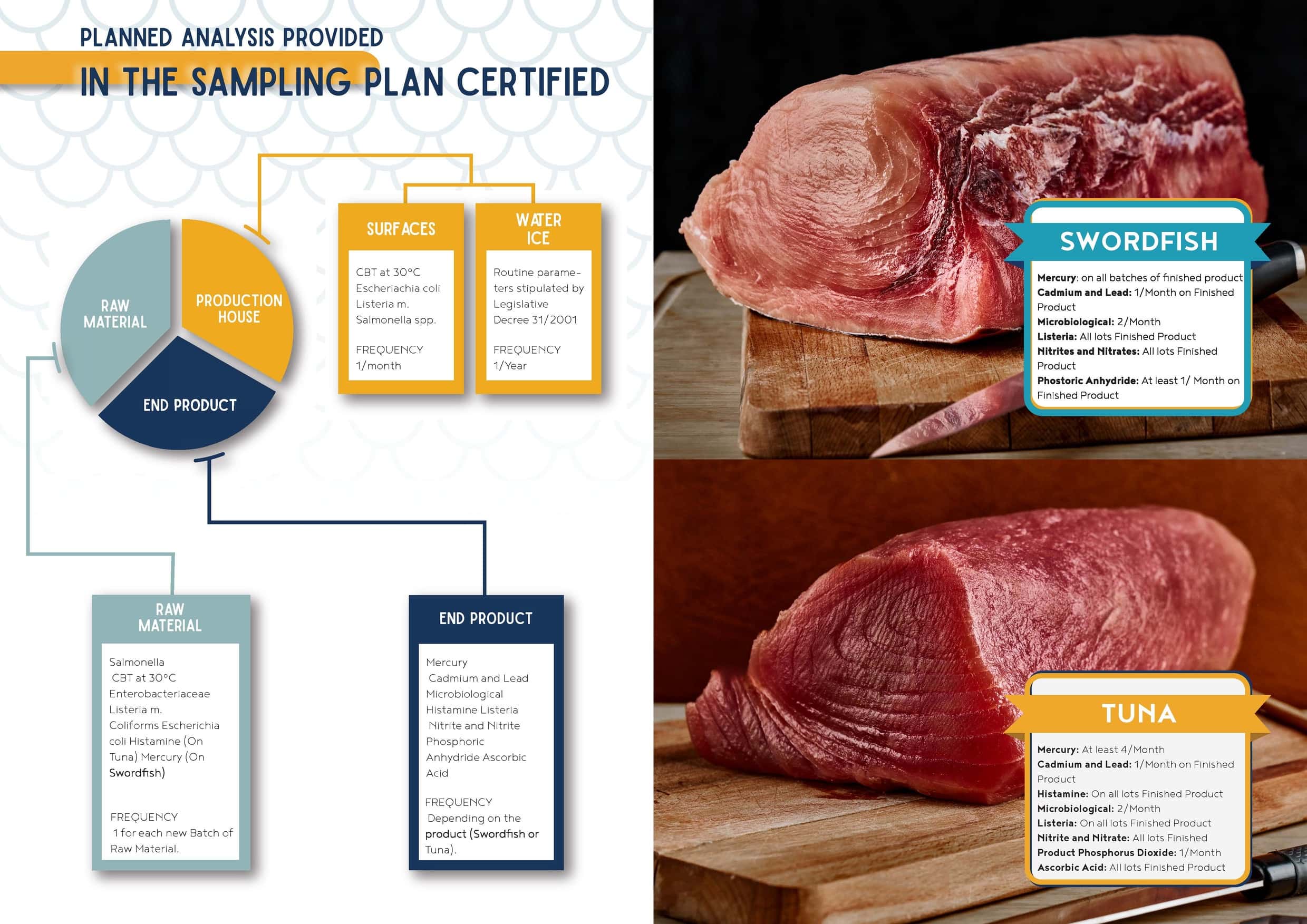

Through a detailed sampling and analysis plan on our products, we guarantee high standards of food quality and safety appreciated by our customers and end consumers.

Navigated

craftmanship

Within certified laboratories, Sea Master conducts both defrost and catch production.

We are proud to offer vacuum-packed products with MOCAs (Materials and Objects in Contact with Food that comply with Italian and European regulations) and authorised additives (EU Regulation 1333/2008 ).

Precisely to guarantee the consumer a safe product, Sea Master uses certified laboratories to test for heavy metals.

Not only that: from fishing to delivery we work to minimise histamine presence, a nitrogen compound that when present in excessive amounts in food causes mackerel syndrome, an intoxication so called because among the main foods that trigger it are fishes of the family Scombridae, to which tuna belongs. The maximum quantity permitted in fish products, methods of analysis and sampling plans are defined by Regulation (EC) 1441/2007, which we adhere to.

Since histamine formation in fish is only minimally due to autolytic phenomena related to the death of the animal, the problem can and must be controlled.

First of all, we know that the accumulation of histamine is favoured by higher temperatures, which is why we immediately deep froze the meat and respect the cold chain from the start of processing to the final delivery of the product.

Secondly, among the main causes of histamine formation is the proliferation of exogenous bacteria that contaminate meat; evisceration and gill removal can prevent this from happening, provided these operations are carried out in strictly hygienic environments, such as those in our factories. Thanks to our certifications, we guarantee our customers maximum food safety, including packaging in sterile environments.

We work in the conviction that our commitment to quality and safety is appreciated not only by our customers, but also by final consumers, who are increasingly informed and aware. According to an EFSA (European Food Safety Authority) survey, two out of five Europeans took an active interest in food safety in 2019. Looking to the future, we bet this number will grow. We are ready.